MultiGrip Rivets: Achieve Manufacturing Efficiency for applications with multiple material thicknesses

Managing a diverse inventory of rivets is a common challenge in manufacturing. From operator errors to the complexities of stack sizes and inconsistent hole sizes, the process can become a logistical headache. Enter MultiGrip rivets—a transformative solution that simplifies inventory management and boosts efficiency.

Managing a diverse inventory of rivets is a common challenge in manufacturing. From operator errors to the complexities of stack sizes and inconsistent hole sizes, the process can become a logistical headache. Enter MultiGrip rivets—a transformative solution that simplifies inventory management and boosts efficiency.

Consolidate, Simplify, and Save

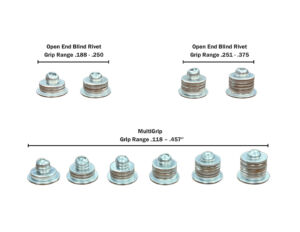

MultiGrip rivets are designed to consolidate several rivet sizes into a single part, streamlining your inventory and production process. Here’s how they make a difference:

· Fewer Part Numbers to Manage: With MultiGrip rivets, you can reduce the number of part numbers in your inventory. A single MultiGrip rivet can replace multiple traditional rivets, simplifying stock management.

· Increased Flexibility: One of the key advantages of MultiGrip rivets is their ability to handle variable material thicknesses. This flexibility ensures that you don’t need to worry about finding the perfect rivet for each material, as MultiGrip rivets can accommodate a wider range.

· Enhanced Accuracy: Mistakes happen, especially when rivets that appear identical have different grip ranges. With MultiGrip rivets, you reduce the risk of errors, as these versatile rivets cover multiple grip ranges.

· Automation-Friendly: If you’re automating your riveting process, MultiGrip rivets are an excellent choice. Their single rivet feed system simplifies the process, allowing for faster and more accurate production.

Benefits of MultiGrip Rivets

· Broader Grip Range: A single MultiGrip rivet can cover the grip range of 2-3 standard rivets, reducing the need for multiple sizes and further simplifying inventory management.

· Compensates for Variations: MultiGrip rivets are designed to compensate for variations in grip range and hole size, making them versatile and forgiving when it comes to inconsistencies in manufacturing.

· BSR Prevention: In automotive and other industries, buzz, squeak, and rattle (BSR) can be a significant concern. MultiGrip rivets help prevent BSR by securing the mandrel ball, ensuring a tight, reliable fit. Additionally, they eliminate the risk of conductive debris, which can cause issues in sensitive electronic assemblies.

Choosing the Right Type: RT vs. CT

MultiGrip rivets come in two main types—Ring Type (RT) and Crimp Type (CT)—each offering distinct advantages depending on your application needs.

· Crimp Type (CT): For applications that demand superior strength and hole fill, CT rivets excel. Their crimp design enhances the connection, providing greater durability and strength in the assembly.

· Ring Type (RT): This type features rolled rings, offering a clean, smooth finish without sharp corners. If aesthetic appeal is important, especially for the backside of the assembly, RT rivets are the ideal choice.

Why MultiGrip Rivets are a Game-Changer

In fast-paced manufacturing environments, efficiency is key. MultiGrip rivets not only streamline inventory and reduce errors but also enhance the overall quality of your assembly. By accommodating variable material thicknesses and hole sizes, these versatile rivets ensure a more consistent, reliable manufacturing process.

Whether you’re looking to cut down on part numbers, improve accuracy, or prevent common issues like BSR, MultiGrip rivets offer a one-size-fits-all solution that delivers.

Upgrade your riveting process with MultiGrip rivets and experience the difference in flexibility, reliability, and efficiency.