PokaYoke FreeSet® Module for Rivet Nuts

PokaYoke FreeSet® Module for Rivet Nuts

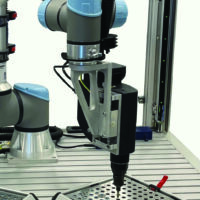

FreeSet® RK-Roboriv is optimized for process monitoring in automated robotic operations for Poka-Yoke implementation in production lines. Using a load cell combined with a stroke sensor, it’s possible to measure the installation force to detect and avoid inconsistences in clamp load as a result of human-error, maintenance, or set-up. A force controlled strategy prevents spin-out and improves mandrel life caused by over or under tightening. This empowers management to standardize the training process, promote work improvement-oriented actions, unburden quality control staff and prevent/detect/eliminate defects before reaching customers. The FreeSet® Manager software helps analyze, configure and control the application of rivet nuts as well as the tools configuration and preventive maintenance plan.

PASS/FAIL: The results of the riveting process inform the operator via the OLED screen, or to external systems via WIFI.

- Models

- Video

- Product Assistance

- Features/Benefits

- Download

- Catalog

| Model# | Capacity | Max Force | Speed | USB | Scanner | WiFi |

| RK-ROBORIV | 3/8″/M10* | 4000 lbs. | 35mm/sec | yes | optional | optional |

*Tool capacity is subject to max force value.

Industrial Rivet & Fastener Co. can help you select the right product or tool for your application. Please contact our experienced Product Specialists with any questions. We look forward to hearing from you! 1-800-BUY-RIVET or info@rivet.com

Safer Work Environment

• Eliminates trip hazards

• Improved ergonomics – no hose to drag around

• No hoses to dirty or scratch painted or finished surfaces

• Improves air quality by eliminating oil emitted with the air Increased Efficiency

• QuickDraw™ Technology drastically increases tool speed

• Cordless tools use 99% less energy than air tools

• No pressure drops caused by compressors

• No maintenance of oilers

• No more supply line leaks Freeset™ tools with QuickDraw™ Technology are faster than pneudraulic and hydraulic tools. They can detect when a rivet is applied and quickly reset without having to complete an entire stroke cycle.

• 18V, 2.5 Ah Lithium Ion battery

• 12-month warranty against manufacturing defects

• Tool does not come supplied with nosepieces – they must be ordered separately Freeset™ tools have a battery management system that prevents users from starting a job if the battery life is too low. This eliminates the risk of the tool shutting down mid-installation and not setting the lockbolt properly.

CAUTION: When operating always wear safety glasses to protect your eyes.

Increased Quality of riveted joints:

- Robot/Cobot Assisted

- Pressure Trigger (if configured)

- Error Proofing

- Process Monitoring and Error Proofing Features

- Freeset Manager Software

- Configurable Settings

- Maintenance Reminders

- Rivet Counting

- Riveting Job Management

- Wifi Communication with external devices

- Barcode Reader

- Pressure Trigger

- Graphical Analysis

- Pass/Fail